Determination of the absolute hardness of electrolytically produced copper coatings by application of the Chicot–Lesage composite hardness model Scientific paper

Main Article Content

Abstract

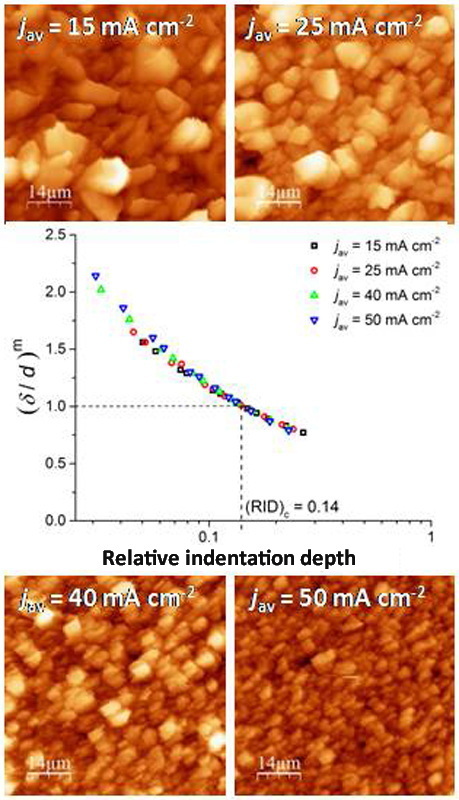

In this study, a novel procedure, based on application of the Chicot–Lesage (C–L) composite hardness model, was proposed for the determination of an absolute hardness of electrolytically produced copper coatings. The Cu coatings were electrodeposited on the Si(111) substrate by the pulsating current (PC) regime with a variation of the following parameters: the pause duration, the current density amplitude and the coating thickness. The topography of produced coatings was characterized by atomic force microscope (AFM), while a hardness of the coatings was examined by Vickers microindentation test. Applying the C–L model, the critical relative indentation depth (RID)c of 0.14 was determined, which is independent of all examined parameters of the PC regime. This RID value separated the area in which the composite hardness of the Cu coating corresponded to its absolute hardness (RID < 0.14) from the area in which the application of the C–L model was necessary for a determination of the absolute coating hardness (RID ³ 0.14). The obtained value was in a good agreement with the value already published in the literature.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-9/2021-14/200026;451-03-9/2021-14/200135

References

Copper, https://www.sharrettsplating.com/coatings/copper (accessed on 23 August 2021)

N. Bharadishettar, U. K. Bhat, D. B. Panemangalore, Metals 11 (2021) 711 (https://doi.org/10.3390/met11050711)

K. I. Popov, S. S. Djokić, N. D. Nikolić, V. D. Jović, Morphology of Electrochemically and Chemically Deposited Metals, Springer International Publishing, 2016 (doi: 10.1007/978-3-319-26073-0)

I. Manika, J. Maniks, J. Phys., D 41 (2008) 074010 (http://dx.doi.org/10.1088/0022-3727/41/7/074010)

J. Lesage, A. Pertuz, E. S. Puchi-Cabrera, D. Chicot, Thin Solid Films 497 (2006) 232 (http://doi:10.1016/j.tsf.2005.09.194)

J. Lesage, D. Chicot, Surf. Coat. Technol. 200 (2005) 886 (https://doi.org/10.1016/j.surfcoat.2005.01.056)

D. Chicot, J. Lesage, Thin Solid Films 254 (1995) 123 (https://doi.org/10.1016/0040-6090(94)06239-H)

I. O. Mladenović, J. S. Lamovec, D. G. Vasiljević Radović, R. Vasilić, V. J. Radojević, N. D. Nikolić, Metals 10 (2020) 488 (https://doi.org/10.3390/met10040488)

J. L. He, W. Z. Li, H. D. Li, Appl. Phys. Lett. 69 (1996) 1402 (https://doi.org/10.1063/1.117595)

Q. Hou, J. Gao, S. Li, Eur. Phys. J., B 8 (1999) 493 (https://doi.org/10.1007/s100510050716)

I. O. Mladenović, J. S. Lamovec, D. G. Vasiljević-Radović, V. J. Radojević, N. D. Nikolić, Int. J. Electrochem. Sci. 15 (2020) 12173 (http://dx.doi.org/10.20964/2020.12.01)

A. M. Korsunsky, M. R. Mc Gurk, S. J. Bull, T. F. Page, Surf. Coat. Technol. 99 (1998) 171 (htps://doi.org/10.1016/S0257-8972(97)00522)

J. R. Tuck, A. M. Korsunsky, S. J. Bull, R. I. Davidson, Surf. Coat. Technol. 137 (2001) 217 (doi:10.1016/S0257-8972(00)01063-X)

J. Lamovec, V. Jovic, D. Randjelovic, R. Aleksic, V. Radojevic, Thin Solid Films 516 (2008) 8646 (https://doi.org/10.1016/j.tsf.2008.06.035)

I. O. Mladenović, J. S. Lamovec, V. B. Jović, M. Obradov, D. G. Vasiljević Radović, N. D. Nikolić, V. J. Radojević, J. Serb. Chem. Soc. 84 (2019) 729 (https://doi.org/10.2298/JSC181003023M)

D. Lebouvier, P. Gilormini, E. Felder, Thin Solid Films 172 (1989) 227 (https://doi.org/10.1016/0040-6090(89)90651-2)

S. J. Bull, J. Phys., D 38 (2005) R393 (https://doi.org/10.1088/0022-3727/38/24/R01)

D. E. Kramer, A. A. Volinsky, N. R. Moody, W. W. Gerberich, J. Mater. Res. 16 (2001) 3150 (https://doi.org/10.1557/JMR.2001.0434)

T. W. Wu, M. Moshref, P. S. Alexopoulos, Thin Solid Films 187 (1990) 295 (https://doi.org/10.1016/0040-6090(90)90051-E)

D. Beegan, S. Chowdhury, M.T. Laugier, Thin Solid Films 466 (2004) 167 (https://doi.org/10.1016/j.tsf.2004.03.006)

I. O. Mladenović, N. D. Nikolić, J. S. Lamovec, D. Vasiljević-Radović, V. Radojević, Metals 11 (2021) 111 (https://doi.org/10.3390/met11010111)

I. Horcas, R. Fernández, J. M. Gómez-Rodríguez, J. Colchero, J. Gómez-Herrero, A. M. Baro, Rev. Sci. Instrum. 78 (2007) 013705 (doi:10.1063/1.2432410)

I. Manika, J. Maniks, Thin Solid Films 208 (1992) 223 (https://doi.org/10.1016/0040-6090(92)90646-S).