Homogeneous microwave-assisted carboxymethylation from totally chlorine free bleached olive tree pruning residues pulp Scientific paper

Main Article Content

Abstract

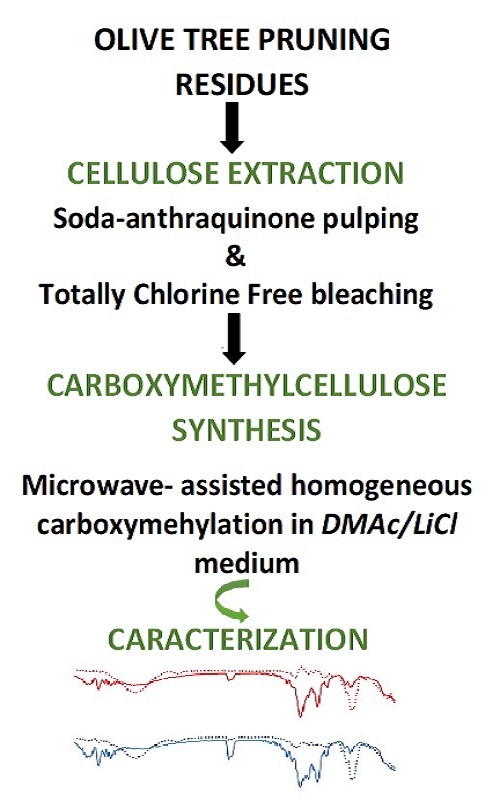

This study deals with a new methodology for the production of carboxymethyl cellulose (CMC) from olive pruning residues, agricultural by-products. Cellulose was extracted by the soda–anthraquinone pulping process, and the pulp bleaching was performed using totally chlorine free (TCF) bleaching. Then, CMC microwave-assisted synthesis was performed in a homogeneous media, using DMA/LiCl as a cellulose solvent. A Box–Behnken design was applied in order to evaluate which parameters of the carboxymethylation process (viz. reaction time, reaction temperature, and amount of monochloroacetic acid) affect the degree of substitution and the yield of the synthesis reaction of this cellulose derivative. Optimized conditions to yield CMC were determined based on the desirability function approach. The prepared materials under synthesis using the optimal conditions were characterized using several analytical tools, i.e., FTIR, TGA, DSC and SEM. This cellulose derivative was successfully fabricated by a fast and efficient microwave-assisted method and thus would provide many opportunities for diverse applications.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

A. Bono, P. H. Ying, yan yan Farm, C. L. Muei, R. Sarbatly, D. Krishnaiah, ANAS 3 (2009) 5 (https://www.researchgate.net/publication/279598236_Synthesis_and_-characterization_of_carboxymethyl_cellulose_from_palm_kernel_cake)

R. K. Singh, A. K. Singh, Waste Biomass Valor. 4 (2013) 129 (https://doi.org/10.1007/s12649-012-9123-9)

M. Sain, S. Panthapulakkal, Ind. Crops Prod. 23 (2006) 1 (https://doi.org/10.1016/j.indcrop.2005.01.006)

A. Nefzaoui, in Fourrages et Sous-Produits Méditerranéens, X. Alibés, J.-L. Tisserand, Eds., CIHEAM, Zaragoza, 1991, pp. 101–108 (http://om.ciheam.org/om/pdf/a16/91605051.pdf)

T. Heinze, A. Koschella, Macromol. Symp. 223 (2005) 13 (https://doi.org/10.1002/masy.200550502)

G. Zhang, L. Zhang, H. Deng, P. Sun, J. Chem. Technol. Biotechnol. 86 (2011) 584 (https://doi.org/10.1002/jctb.2556)

T. Heinze, U. Erler, I. Nehls, D. Klemm, Angew. Makromol. Chem. 215 (1994) 93 (https://doi.org/10.1002/apmc.1994.052150108)

S. Sen, J. D. Martin, D. S. Argyropoulos, ACS Sustain. Chem. Eng. 1 (2013) 858 (https://doi.org/10.1021/sc400085a)

S. Fischer, H. Leipner, E. Brendler, W. Voigt, K. Fischer, in Polysaccharide Applications, American Chemical Society, Washington, DC, 1999, pp. 143–150 (https://10.1021/bk-1999-0737.ch010)

M. B. Gawande, S. N. Shelke, R. Zboril, R. S. Varma, Acc. Chem. Res. 47 (2014) 1338 (https://doi.org/10.1021/ar400309b)

J. D. Moseley, C. O. Kappe, Green Chem. 13 (2011) 794 (https://doi.org/10.1039/C0GC00823K)

S. Caddick, R. Fitzmaurice, Tetrahedron 65 (2009) 3325 (https://doi.org/10.1016/j.tet.2009.01.105)

M. Nüchter, B. Ondruschka, W. Bonrath, A. Gum, Green Chem. 6 (2004) 128 (https://doi.org/10.1039/B310502D)

Y.-J. Zhu, F. Chen, Chem. Rev. 114 (2014) 6462 (https://doi.org/10.1021/cr400366s)

J. Li, L.-P. Zhang, F. Peng, J. Bian, T.-Q. Yuan, F. Xu, R.-C. Sun, Molecules 14 (2009) 3551 (https://doi.org/10.3390/molecules14093551)

A. Biswas, S. Kim, G. W. Selling, H. Cheng, Ind Crops Prod. 60 (2014) 259 (https://doi.org/10.1016/j.indcrop.2014.06.004)

B. Martín-García, S. Pimentel-Moral, A. M. Gómez-Caravaca, D. Arráez-Román, A. Segura-Carretero, Ind Crops Prod. 154 (2020) 112741 (https://doi.org/10.1016/j.indcrop.2020.112741)

T. Salmi, D. Valtakari, E. Paatero, B. Holmbom, R. Sjoholm, Ind. Eng. Chem. Res. 33 (1994) 1454 (https://doi.org/10.1021/ie00030a004)

A. M. Joglekar, A. T. May, CFW 32 (1987) 857 (https://www.semanticscholar.org/paper/Product-excellence-through-design-of-experiments-Joglekar-May/927ffd1c557062b82f407ad08d82122af959827c)

L. Manzato, M. L. Takeno, W. A. G. Pessoa-Junior, L. A. M. Mariuba, J. Simonsen, Fibers Polym. 19 (2018) 289 (https://doi.org/10.1007/s12221-018-1123-8)

P. Penjumras, R. B. A. Rahman, R. A. Talib, K. Abdan, Agric. Agric. Sci. Proc. 2 (2014) 237 (https://doi.org/10.1016/j.aaspro.2014.11.034)

X. F. Sun, F. Xu, R. C. Sun, P. Fowler, M. S. Baird, Carbohydr. Res. 340 (2005) 97 (https://doi.org/10.1016/j.carres.2004.10.022)

A. Mandal, D. Chakrabarty, Carbohydr. Polym. 86 (2011) 1291 (https://doi.org/10.1016/j.carbpol.2011.06.030)

N. Laribi, S. Maatoug, Z. Jebali, R. Zouari, H. Majdoub, M. Cheikhrouhou, Cellul. Chem. Technol. 54 (2020) 225 (https://doi.org/10.35812/CelluloseChemTechnol.2020.54.24)

S. M. L. Rosa, N. Rehman, M. I. G. de Miranda, S. M. B. Nachtigall, C. I. D. Bica, Carbohydr. Polym. 87 (2012) 1131 (https://doi.org/10.1016/j.carbpol.2011.08.084)

M. Adinugraha, D. Marseno, Haryadi, Carbohydr. Polym. 62 (2005) 164 (https://doi.org/10.1016/j.carbpol.2005.07.019)

G. A. Zickler, W. Wagermaier, S. S. Funari, M. Burghammer, O. Paris, J. Anal. Appl. Pyrolysis 80 (2007) 134 (https://doi.org/10.1016/j.jaap.2007.01.011)

A. N. Shebani, A. J. van Reenen, M. Meincken, Thermochim. Acta 471 (2008) 43 (https://doi.org/10.1016/j.tca.2008.02.020)

C. Leyva-Porras, P. Cruz-Alcantar, V. Espinosa-Solís, E. Martínez-Guerra, C. I. Piñón-

-Balderrama, I. Compean Martínez, M. Z. Saavedra-Leos, Polymers (Basel) 12 (2019) 5 (https://doi.org/10.3390/polym12010005).