Preventing hydrolysis of AlN powders with organophosphate coating in aqueous media Scientific paper

Main Article Content

Abstract

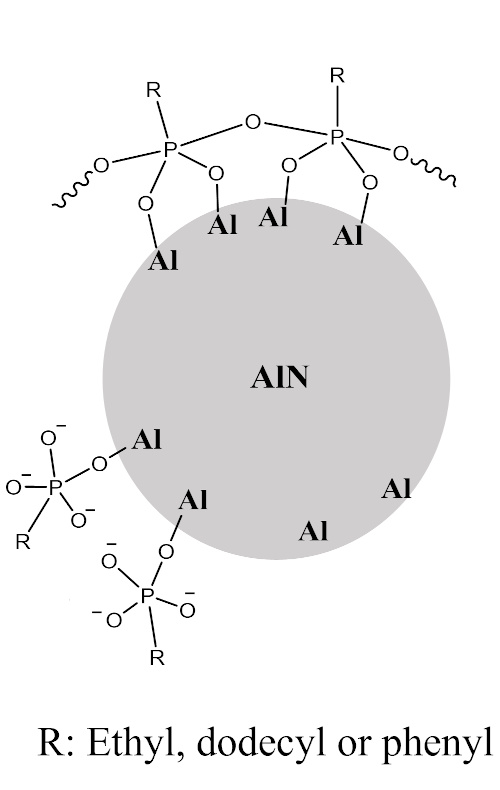

The coating of aluminum nitride powder has a great importance industrially and environmentally. AlN can be rapidly hydrolyzed to aluminum hydroxide and ammonia in the atmosphere or water media. To prevent the hydrolysis of AlN, the inorganic or organic based coatings are used frequently. For the first time, this study describes the phosphate esters as organophosphate coating used for the inhibition of hydrolysis reaction of AlN in its water suspension. Phenyl phosphate showed the best inhibition against AlN hydrolysis with an easy application technique and at low concentration of 0.005 M. AlN coating efficiency was proved by spectroscopic and imaging methods. It was concluded that the coating acquired the protective properties of phenyl phosphate through its water repellence.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Funding data

-

Gazi Üniversitesi

Grant numbers (Project Numbers: 05/2017-04) -

Türkiye Bilimsel ve Teknolojik Araştırma Kurumu

Grant numbers 1929B011800196

References

L. M. Sheppard, Am. Ceram. Soc. Bull. 69 (1990) 1801

G. Hu, C. Q. Chen, K. T. Ramesh, J. W. McCauley, Acta Materialia 60 (2012) 3480 (https://doi.org/10.1016/j.actamat.2012.03.011)

J. L. Qi, L. P. Wang, Y. Zhang, X. Guo, W. Yu, Q. Wang, K. Zhang, P. Ren, M. Wen, Surf. Coat. Technol. 405 (2021) 126724 (https://doi.org/10.1016/j.surfcoat.2020.126724)

Q. Wang, Y. Lu, S. Mishin, Y. Oshmyansky, D. A. Horsley, J. Microelectromechanical Syst. 26 (2017) 1132 (https://doi.org/10.1109/JMEMS.2017.2712101)

S. Hao, L. Zhang, X. Wang, G. Zhao, P. Hou, X. Xu, Energy & Fuels 35 (2021) 12628 (https://doi.org/10.1021/acs.energyfuels.1c01420)

J. Li, M. Nakamura, T. Shirai, K. Matsumaru, C. Ishizaki, K. Ishizaki, J. Am. Ceram. Soc. 89 (2006) 937 (https://doi.org/10.1111/j.1551-2916.2005.00767.x)

A. Kocjan, A. Dakskobler, K. Krnel, T. Kosmač, J. Eur. Ceram. Soc. 31 (2011) 815 (https://doi.org/10.1016/j.jeurceramsoc.2010.12.009) .

G. Long, L. M. Foster, J. Am. Ceram. Soc. 42 (1959) 53 (https://doi.org/10.1111/j.1151-2916.1959.tb14066.x)

H. Feng, G. Zhang, Q.. Yang, L. Xun, S. Zhen, D. Liu, Processes 8 (2020) 1269 (https://doi.org/10.3390/pr8101269)

M. Mahinroosta, A. Allahverdi, J. Environ. Manage. 223 (2018) 452 (https://doi.org/10.1016/j.jenvman.2018.06.068)

S. Fukumoto, T. Hookabe, H. Tsubakino, J. Materials Sci. 35 (2000), 2743 (https://doi.org/10.1023/A:1004718329003)

M. Oliveira, S. Olhero, J. Rocha, J. M. F. Ferreira, J. Colloid Interface Sci. 261 (2003), 456 (https://doi.org/10.1016/S0021-9797(03)00065-1)

R. Senthil Kumar, K. Rajeswari, B. Praveen, U. N. S. Hareesh, R. Johnson, J. Am. Ceram. Soc. 93 (2010) 429 (https://doi.org/10.1111/j.1551-2916.2009.03418.x)

Q. Wang, S. M. Olhero, J. M. F. Ferreira, W. Cui, K. Chen, Z. Xie, R. Riman, J. Am. Ceram. Soc. 96 (2013) 1383 (https://doi.org/10.1111/jace.12288)

Y. H. Koh, J. J. Choi, H. E. Kim, J. Am. Ceram. Soc. 83 (2000) 306 (https://doi.org/10.1111/j.1151-2916.2000.tb01190.x)

Y. Shimizu, J. Hatano, T. Hyodo, M. Egashira J. Am. Ceram. Soc. 83 (2000) 2793 (https://doi.org/10.1111/j.1151-2916.2000.tb01633.x)

S. Wildhack, G. Rixecker, F. Aldinger, J. Am. Ceram. Soc. 83 (2005) 2391 (https://doi.org/10.1111/j.1551-2916.2005.00467.x)

H. B. Shan, Y. Zhu, Z. T. Zhang, Br. Ceram. Trans. 98 (1999) 146 (https://doi.org/10.1179/096797899680363)

G. Yu, J. Xie, S. Wang, Y. Wang, T. Wang, L. Fan, L. Zhang, F. Lei, Y. Shi, L. Yu, Ceram. Int. 47 (2021) 29253 (https://doi.org/10.1016/j.ceramint.2021.07.089)

M. Egashira, Y. Shimizu, S. Takatsuki, J. Mater. Sci. Lett. 10 () 994 (https://doi.org/10.1007/BF00721824)

A. Kocjan, A. Dakskobler, T. Kosmac, Int. J. Appl. Ceram. Technol. 8 (2011) 853 (https://doi.org/10.1111/j.1744-7402.2010.02516.x)

R. S. Kumar, U. S. Hareesh, P. Ramavath, R. Johnson, Ceram. Int. 37 (2011) 2583 (https://doi.org/10.1016/j.ceramint.2011.04.131)