Inhibition study of curcumin extract’s effect on dissimilar aluminium joint Scientific paper

Main Article Content

Abstract

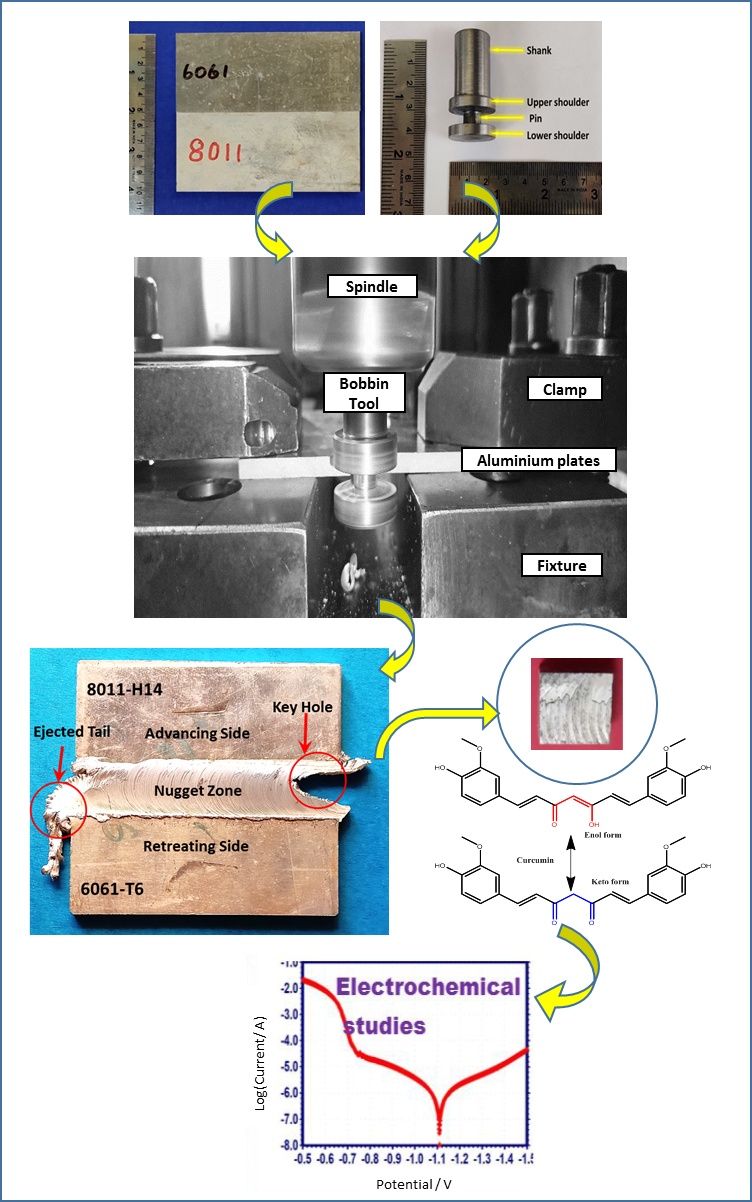

Aluminium welded joints are offering greater interest to researchers owing to the replacement of heavy steel structures and reduction in the weight of the components used in the automobile and marine environments. In this study AA6061 and AA8011 have been welded by using the bobbin tool friction stir welding method and by varying the process parameters with the samples being subjected to corrosion environments. The corrosive nature of the welded alloys in the absence and presence of inhibitors (curcumin) has been examined by electrochemical methods and compared with raw samples. The ratio has been observed between 0.075 and 5.42 A cm-2. The results reveal that corrosion control tendency has been improved by the AA6061 and AA8011 aluminium alloy joint in the presence of curcumin extract.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, W.S. Miller, Mater. Sci. Eng., A 280 (2000) 102 (https://doi.org/10.1016/s0921-5093(99)00674-7)

T. Dursun, C. Soutis, Mater. Des. 56 (2014) 862 (https://doi.org/10.1016/j.matdes.2013.12.002)

J. Hirsch, Trans. Nonferrous Met. Soc. China 24 (2014) 1995 (https://doi.org/10.1016/S1003-6326(14)63305-7)

C.H. Ng, S. N. M. Yahaya, A. A. A. Majid, Acad. J. Sci. Res. 5 (2017) 708 (https://academiapublishing.org/journals/ajsr/pdf/2017/Dec/Ng%20et%20al.pdf)

T. Trzepiecinski, Metals 10 (2020) 779 (https://doi.org/10.3390/met10060779)

D. Feron, Corrosion Behaviour and Protection of Copper and Aluminium Alloys in Seawater, Europ. Fed. Corros. Ser., 2007, pp. 145–155 (eBook ISBN: 9781845693084)

T. Watanabe, H. Takayama, A. Yanagisawa, J. Mater. Process. Technol. 178 (2006) 342 (https://doi.org/10.1016/j.jmatprotec.2006.04.117)

M. Khafri, J. Mater. Sci. 39 (2004) 6467 (https://doi.org/10.1023/B:JMSC.0000044884.25589.9b)

M. Esmaily, N. Mortazavi, W. Osikowicz, Mater. Des. 108 (2016) 114 (https://doi.org/10.1016/j.matdes.2016.06.089)

W. Y. Li, T. Fu, L. Hutsch, J. Hilgert, F. F. Wang, J. F. Dos Santos, N. Huber, Mater. Des. 64 (2014) 714 (https://doi.org/10.1016/j.matdes.2014.07.023)

K. Xhanari, M. Finsgar, Int. J. Electrochem. Sci. 12 (2017) 5845 (https://doi.org/10.20964/2017.07.71)

J.C. Swearengen, Mater. Sci. Eng. 10 (1972) 103 (https://doi.org/10.1016/0025-5416(72)90074-2)

J. Fayomi, A.P.I. Popoola, O.M. Popoola, O.S.I. Fayomi, J. Alloys Compd. 850 (2021) 1 (https://doi.org/10.1016/j.jallcom.2020.156679)

C. Shujin, Li. Hao, Lu. Sheng, Ni. Ruiyang, D. Jianghui, Int. J. Adv. Manuf. Technol. 86 (2016) 337 (https://doi.org/10.1007/s00170-015-8116-9)

D. Ji-Hong, G. Chong, L. Yao, H. Jain, J. Xiang-Dong, Z. Zhi-Xiong, Int. J. Min. Met. Mater. 24 (2017) 171 (https://doi.org/10.1007/s12613-017-1392-7)

R. Rosliza, W.B. Wan Nik, H.B. Senin, Mater. Chem. Phys. 107 (2008) 281 (https://doi.org/10.1016/j.matchemphys.2007.07.013)

M. K. Abbass, K. S. Hassan, A. S. Alwan, Int. J. Manuf. Mater. Mech. Eng. 3 (2015) 31 (https://doi.org/10.7763/IJMMM.2015.V3.161)

N. Sunitha, K.G. Manjunatha, S. Khan, M. Sravanthi, SN Appl. Sci. 1 (2019) 1024 (https://doi.org/10.1007/s42452-019-1063-6)

M. Mardalizadeh, M. Khandaei, M. Safarkhanian, J. Adhes. Sci. Technol. 35 (2020) 1 (https://doi.org/10.1080/01694243.2020.1792156)

M. K. Sued, D. Pons, J. Lavroff, E. H. Wong, Mater. Des. 54 (2014) 632 (https://doi.org/10.1016/j.matdes.2013.08.057)

M. M. Z. Ahmed, M. I. A. Habba, M. M. El-Sayed Seleman, K. Hajlaoui, S. Ataya, F. H. Latief, A. E. El-Nikhaily, Materials 14 (2021) 4585 (https://doi.org/10.3390/ma14164585)

W. Y. Li, T. Fu, L. Hutsch, J. Hilgert, F. F. Wang, J. F. Dos Santos, N. Huber, Mater. Des. 64 (2014) 714 (https://doi.org/10.1016/j.matdes.2014.07.023)

Y. Li, D. Sun, W. Gong, Metals 9 (2019) 894 (https://doi.org/10.3390/met9080894)

S. Sinhmar, D. K. Dwivedi, Corros. Sci. 133 (2018) 25 (https://doi.org/10.1016/j.corsci.2018.01.012)

F. Gharavi, K. A. Matori, R. Yunus, N. K. Othman, Mater. Res. 17 (2014) 672 (https://doi.org/10.1590/S1516-14392014005000053)

X. G. Zhang, Corrosion and Electrochemistry of Zinc, 1st ed., Springer, New York, 1996, pp. 125–156 (https://doi.org/10.1007/978-1-4757-9877-7_5)

S. B. Strbac, R. R. Adzic, in Encyclopedia of Applied Electrochemistry , G. Kreysa, K. Ota, R. F. Savinell, Eds., Springer, Berlin, 2014, p. 417 (https://doi.org/10.1007/978-1-4419-6996-5_485)

H. Elmsellem, M. H. Youssouf, A. Aouniti, T. Ben Hadda, A. Chetouani, B. Hammouti, Russ. J. Appl. Chem. 87 (2014) 744 (https://doi.org/10.1134/s1070427214060147)

L. Juhaiman, Green Sustain. Chem. 6 (2016) 57 (https://doi.org/10.4236/gsc.2016.62005)

E. A. Flores-Frias, V. Barba, R. Lopez-Sesenes, L. L. Landeros-Martinez, J. P. Flores-De Los Rios, M. Casales, J. G. Gonzalez-Rodriguez, Int. J. Electrochem. Sci. 14 (2019) 5026 (https://doi.org/10.20964/2019.06.53)

Y. Yan, Metal. Biomed. Devices. 1 (2010) 178 (https://doi.org/10.1533/9781845699246.2.178)

Y. Yan, A. Neville, and D. Dowson, J. Phys., D 39 (2006) 3200 (https://doi.org/10.1088/0022-3727/39/15/S10)

J. G. Speight, P. J. Subsea, Deepwater Oil and Gas Science and Technology, 1st ed., Gulf Professional, Oxford, 2012, p. 213 (https://doi.org/10.1016/B978-1-85617-558-6.00008-8)

F. Gharavi, K. Matori, R. Yunus, N. Othman, F. Fadaeifard, J. Mater. Res. Technol. 4 (2015) 314 (https://doi.org/10.1016/j.jmrt.2015.01.007)

R. Rosliza, W. B. Wan Nik, Curr. Appl. Phys. 10 (2010) 221 (https://doi.org/10.1016/j.cap.2009.05.027)

J. M. G. De Salazar, A. Urena, S. Manzanedo, M. I. Barrena, Corr. Sci. 41 (1998) 529 (https://doi.org/10.1016/s0010-938x(98)00135-8)

S. T. Selvamani, J. Mater. Res. Technol. 15 (2021) 315 (https://doi.org/10.1016/j.jmrt.2021.08.005)

K. Hornbostel, C. K. Larsen, M. R. Geiker, Cement Concrete Composites 39 (2013) 60 (https://doi.org/10.1016/j.cemconcomp.2013.03.019)

B. T. Ogunsemi, T. E. Abioye, T. I. Ogedengbe, H. Zuhailawati, J. Mater. Res. Technol. 11 (2021) 1061 (https://doi.org/10.1016/j.jmrt.2021.01.070).