Synthesis of zeolite LTA from kaolin and its model CBC and WAC performance: Optimized by central composite design Scientific paper

Main Article Content

Abstract

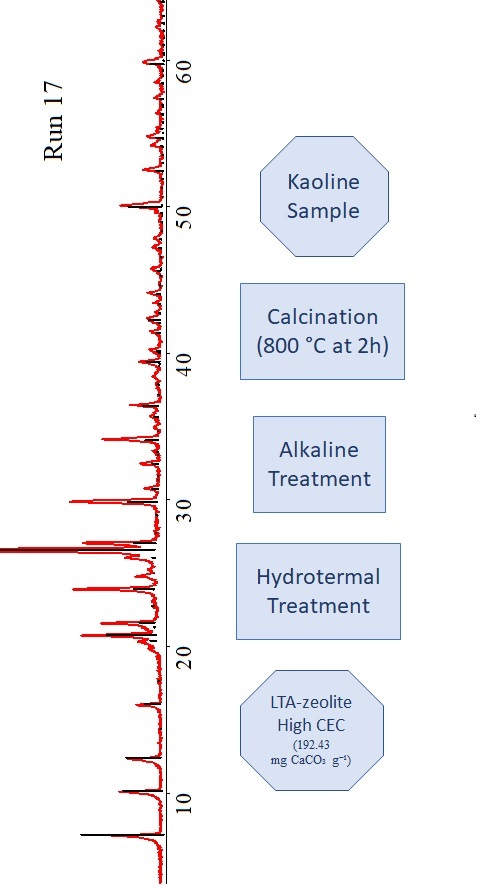

In this study, a cost-effective route to synthesizing LTA-type zeolite from Balıkesir-region kaolin was demonstrated. Kaolin was calcined at 800 °C to obtain metakaolin, which was then treated hydrothermally in the presence of NaOH under optimized conditions determined by a Box–Behnken experimental design. The process variables NaOH concentration, temperature, and solid to liquid ratio were systematically investigated to maximize both water adsorption capacity and cation-exchange capacity (CEC). Quadratic regression models and ANOVA confirmed that NaOH concentration and temperature exert the most significant impact on zeolite formation and performance. Characterization by XRD, SEM and FTIR confirmed that the synthesized product under optimal conditions predominantly consisted of LTA-type zeolite crystals, as evidenced by the characteristic diffraction peaks, morphology and vibrational bands. The best performing sample showed a CEC of up to 192 mg CaCO3 g-1 and a water adsorption capacity of nearly 29 g H2O per 100 g adsorbent. These results highlight the potential of locally sourced kaolin for producing high value zeolites, offering a sustainable alternative to imported raw materials.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

C. Ronco, R. Bellomo, Crit. Care 26 (2022) 135 (https://doi.org/10.1186/s13054-022-04009-w)

S. Chatterjee, T. Chatterjee, SH. Woo, Chem. Eng. J. 166 (2011) 168 (https://doi.org/10.1016/j.cej.2010.10.047)

M. Popaliya, A. Mishra, Inter. J. Environ. Sci. Technol. 20 (2023) 12919 (https://doi.org/10.1007/s13762-022-04603-z)

E. M. Flanigen, J. A. Rabo, Micropor. Mesopor. Mater. 47 (2001) 119 (https://doi.org/10.1016/S1387-1811(01)00301-8)

J. B. Adeoye, J. A. Omoleye, M. E. Ojewumi, R. Babalola, Inter. J. Appl. Eng. Res. 12 (2017) 755 (https://www.ripublication.com/ijaer17/ijaerv12n5_27.pdf)

E. Victor, I. P. Okechukwu, C. N. Uchenna, GSJ 10 (2022) 1913 (http://www.globalscientificjournal.com/researchpaper/HYDROTHERMAL_SYNTHESIS_OF_ZEOLITE_Y_FROM_OKPELLA_KAOLIN_CLAY.pdf)

V. Verdoliva, M. Saviano, S. De Luca, Catalysts 9 (2019) 248 (https://doi.org/10.3390/catal9030248)

N. Yu. Ul’yanovaa, E. Yu. Brazovskayaa, O. Yu. Golubevaa, O. V. Shamovab, Petroleum Chem. 63 (2023) 790 (https://doi.org/10.1134/S096554412305002X)

C. Algieri, E. Drioli, Sep. Pur. Tchnol 278 (2022) 119295 (https://doi.org/10.1016/j.seppur.2021.119295)

P. Bai, M. Y. Jeon, L. Ren, C. Knight, M. W. Deem, M. Tsapatsis, J. I. Siepmann, Nat. Commun. 6 (2015) 5912 (https://doi.org/10.1038/ncomms6912)

H. N. Tran, P. V. Viet, H. Chao, Environ. Saf. 147 (2018) 55 (https://doi.org/10.1016/j.ecoenv.2017.08.027)

P. Frontera, S. Candamano, A. Macario, F. Crea, L. A. Scarpino, P. L. Antonucci, Mater. Lett. 104 (2013) 72 (https://doi.org/10.1016/j.matlet.2013.03.138)

H. Zhang, A. Li, W. Zhang, C. Shuang, J. Colloid Interface Sci. 468 (2015) 128 (https://doi.org/10.1016/j.jcis.2015.10.006)

A. Ates, G. Akgül, Pow Tech. 287 (2016) 285 (https://doi.org/10.1016/j.powtec.2015.10.021)

A. A. Ahmed, Z. H. Yamani, Mater. Chem. Phys. 259 (2021) 124181 (https://doi.org/10.1016/j.matchemphys.2020.124181)

C. Baerlocher, L.B. McCusker, Database of Zeolite Structures, 2025, http://www.iza-structure.org/databases/ (accessed on 24 April 2025)

T. Ohgushi, S. Komarneni, A. S. Bhalla, J. Porous Mater. 8 (2001) 23 (https://doi.org/10.1023/A:1026518200875)

W. Wang, Q. Feng, K. Liu, G. Zhang, J. Liu, Y. Huang, Solid State Sci. 39 (2015) 52 (https://doi.org/10.1016/j.solidstatesciences.2014.11.012)

X. Shen, G. Qiu, C. Yue, M. Guo, M. Zhang, Environ. Sci. Pollut. Res. Int. 24 (2017) 21829 (https://doi.org/10.1007/s11356-017-9824-5)

M. K. Seliem, S. Komarneni, Micropor. Mesopor. Mater 228 (2016) 266 (https://doi.org/10.1016/j.micromeso.2016.04.010)

K.S Hui, C. Y. H. Chao, Micropor. Mesopor. Mater 88 (2006) 145 (https://doi.org/10.1016/j.micromeso.2005.09.005)

W. J. Roth, P. Nachtigall, R. E. Morris, J. Cejka. Chem. Rev. 114 (2014) 4807 (https://doi.org/10.1021/cr400600f)

A. E. Gaidoumi, A. C. Benabdallah, B. E. Bali, A. Kherbeche, Arab. J. Sci. Eng. 43 (2017) 191-197 (https://doi.org/10.1007/s13369-017-2768-8)

Hartati, D. Prasetyoko, M. Santoso, I. Qoniah,. W. L Leaw, P. B. D. Firda, H. Nur. J. Chin. Chem. Soc. 67 (2020) 911 (https://doi.org/10.1002/jccs.201900047)

I. Bojaddayni, M. E. Küçük, Y. Ouardi, I. Jilal, S. Barkany, K. Moradi, E. Repo, K. Laatikainen, A. A. Ouammou, Min. Eng. 198 (2023) 108086 (https://doi.org/10.1016/j.mineng.2023.108086)

T. B. H. Nguyen, H. T. Van, Technol. Agron. 4 (2024) e002 (https://doi.org/10.48130/tia-0023-0021)

M. Senila, O. Cadar, Heliyon 10 (2024) 25303 (https://doi.org/10.1016/j.heliyon.2024.e25303)

M. Gougazeh, J. Taibah Univ. Sci. 12 (2018) 247 (https://doi.org/10.1080/16583655.2018.1465714)

Y. Cui, Y. Zheng, W. Wang, Minerals 8 (2018) 338 (https://doi.org/10.3390/min8080338)

M. A. V Villaquirán-Caicedo, R. M. De Gutiérrez, M. Gordillo, N. C. Gallego, Clays Clay Miner. 64 (2016) 75 (https://doi.org/10.1346/CCMN.2016.0640201)

L. Ayele, J. Pérez-Pariente, Y. Chebude, I. Díaz, Micropor. Mesopor. Mater. 215 (2015) 29 (https://doi.org/10.1016/j.micromeso.2015.05.022)

L. Ayele, J. Pérez-Pariente, Y. Chebude, I. Diaz, New J. Chem. 40 (2016) 3440 (https://doi.org/10.1039/c5nj03097h)

S. K. Kirdeciler, B. Akata, Adv. Powder Tech. 31 (2020) 4336 (https://doi.org/10.1016/j.apt.2020.09.012)

B. Ait-Amir, P. Pougnet, A. El-Hami, Embedded Mechatronic Sys. 2nd Ed. 2 (2020) (ISBN: 9781785481901, eBook ISBN: 9780081019566)

M. R. Wang, D. C. Jia, P. G. He, Y. Zhou, Mater. Lett. 64 (2010) 2551 (https://doi.org/10.1016/j.matlet.2010.08.007)

C. Belviso, F. Cavalcante, A. Lettino, S. Fiore, Appl Clay Sci. 80–81 (2013) 162 (https://doi.org/10.1016/j.clay.2013.02.003)

B. B. Sousa, J. A. R. Rego, D. S. B. Brasil, M. C. Martelli, Cerâmica 66 (2020) 404 (https://doi.org/10.1590/0366-69132020663802758)

B. Fabbri, S. Gualtieri, C. Leonardi, Appl. Clay Sci. 73 (2013) 2 (https://doi.org/10.1016/j.clay.2012.09.019)

C. S. Cundy , P. A. Cox , Micropor. Mesopor. Mater. 82 (2005) 1 (https://doi.org/10.1016/j.micromeso.2005.02.016)

M. Alkan, Ç. Hopa, Z. Yilmaz, H. Güler, Micropor. Mesopor. Mater. 86 (2005) 176 (https://doi.org/10.1016/j.micromeso.2005.07.008).