Development of a glass–ceramic composite reinforced with β-wollastonite synthesized via a hydrothermal method Scientific paper

Main Article Content

Abstract

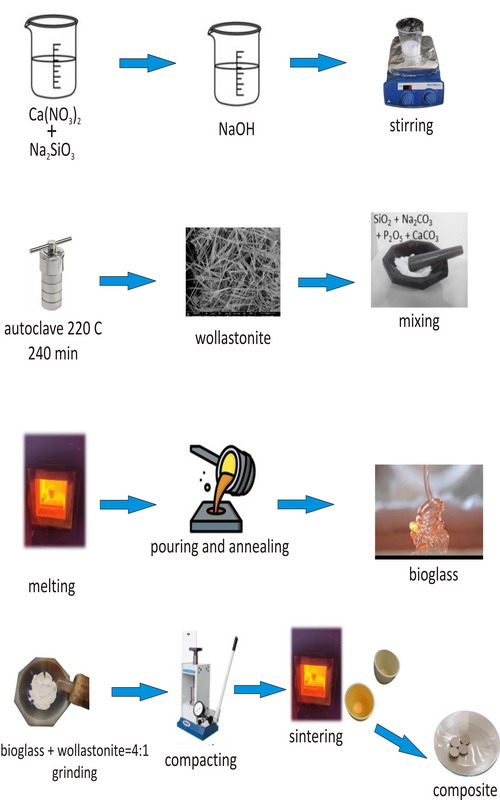

β-wollastonite (β-CaSiO3) microfibres were successfully synthesized using a one-step, template-free hydrothermal reaction involving calcium nitrate and sodium metasilicate in an alkaline medium. The synthesis of microfibres was completed at 220 °C within only 240 min under an autogenous pressure of 19 bar (1.9 MPa). This method avoids the formation of xonotlite as an intermediate phase, eliminating the need for subsequent calcination to achieve wollastonite. X-ray diffraction (XRD) confirmed the β-wollastonite phase, while post-calcination analyses indicated enhanced crystallinity and structural characteristics. Scanning electron microscopy (SEM) revealed a needle-like morphology and N2 adsorption-desorption analysis demonstrated a developed surface area of 26 m2 g-1 with notable mesoporosity. These advantageous features facilitated the integration of β-wollastonite into the synthesis of a glass–ceramic composite, which was characterized for its morphological, structural, textural, and in vitro bioactivity properties. The composite was prepared by mixing β-wollastonite and bioactive glass powders in a 1:4 mass ratio, followed by compaction through uniaxial pressing and sintering at 1000 °C for various time intervals. For comparison, compacted pure bioactive glass samples were also sintered under identical conditions. Structural, morphological, textural and in vitro bioactivity characterizations demonstrated that the incorporation of β-wollastonite led to a more uniform and narrower pore size distribution and promoted neck formation between particles, indicating its potential for bone regeneration applications.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers Agreement number 451-03-137/2025-03/ 200124

References

C. C. Lin, P. Shen, Mater. Chem. Phys. 182 (2016) 508 (https://doi.org/10.1016/j.matchemphys.2016.07.065)

E. Mazzucato, A. F. Gualtieri, Phys. Chem. Miner. 27 (2000) 565 (https://doi.org/10.1007/s002690000095)

K. Lin, J. Chang, G. Chen, M. Ruan, C. Ning, J. Cryst. Growth 300 (2007) 267 (https://doi.org/10.1016/j.jcrysgro.2006.11.215)

K. Lin, C. Lin, Y. Zeng, RSC Adv. 6 (2016) 13867 (https://doi.org/10.1039/c5ra26916d)

M. A. Abdelwahab, A Reflexive Reading of Urban Space, 1st ed., eBook ISBN 9781315565125, Taylor and Francis, London, 2018

N. Obradović, S. Filipović, S. Marković, M. Mitrić, J. Rusmirović, A. Marinković, V. Antić, V. Pavlović, Ceram. Int. 43 (2017) 7461 (https://doi.org/10.1016/j.ceramint.2017.03.021)

W. K. Lam, J. C. Y. Leong, Y. H. Li, Y. Hu, W. W. Lu, Gait Posture 22 (2005) 189 (https://doi.org/10.1016/j.gaitpost.2004.09.011)

V. S. Topalović, S. R. Grujić, V. D. Živanović, S. D. Matijašević, J. D. Nikolić, J. N. Stojanović, S. V. Smiljanić, Ceram. Int. 43 (2017) 12061 (https://doi.org/10.1016/j.ceramint.2017.06.061)

M. Riaz, R. Zia, A. Mirza, T. Hussain, F. Bashir, S. Anjum, Mater. Sci. Eng., C 75 (2017) 872 (https://doi.org/10.1016/j.msec.2017.02.141)

L. Adams, E. R. Essien, R. O. Shaibu, A. Oki, New J. Glass Ceram. 3 (2013) 11 (http://dx.doi.org/10.4236/njgc.2013.31003)

A. Logeshwaran, R. Elsen, S. Nayak, J. Mech. Behav. Biomed. Mater. 138 (2023) 105633 (https://doi.org/10.1016/j.jmbbm.2022.105633)

A. Iatsenko, O. Sych, A. Nikolenko, S. Stelmakh, Results Surf. Interfaces. 16 (2024) 100265 (https://doi.org/10.1016/j.rsurfi.2024.100265)

I. W. Suh, S. R. Jang, E. M. Hia, C. H. Park, C. S. Kim, Mater. Chem. Phys. 326 (2024) 129865 (https://doi.org/10.1016/j.matchemphys.2024.129865)

E. Zeimaran, S. Pourshahrestani, S. F .S. Shirazi, B. Pingguan-Murphy, N. A. Kadri, M.R. Towler, J. Non-Cryst. Solids 443 (2016) 118 (https://doi.org/10.1016/j.jnoncrysol.2016.04.005)

H. Ismail, R. Shamsudin, M. A. A. Hamid, Mater. Sci. Eng., C 58 (2016) 1077 (https://doi.org/10.1016/j.msec.2015.09.030)

B. Chaudhary, Y.K. Kshetri, D.R. Dhakal, S. W. Lee, T. H. Kim, Opt. Mater. 135 (2023) 113326 (https://doi.org/10.1016/j.optmat.2022.113326)

J. Zhu, T. Qu, S. Niu, J. Liu, S. Liu, J. Geng, Z. Yang, A. Abulizi, Mater. Today Sustain. 26 (2024) 100716 (https://doi.org/10.1016/j.mtsust.2024.100716)

A. Sobhani, E. Salimi, Ceram. Int. 50 (2024) 26869 (https://doi.org/10.1016/j.ceramint.2024.04.417)

S. Palakurthy, S. Patel, K. V. Reddy, R. Samudrala, C. Padala, B. Manavathi, P. A. Azeem, Ceram. Int. 49 (2023) 36344 (https://doi.org/10.1016/j.ceramint.2023.08.318)

C. Paluszkiewicz, M. Blażewicz, J. Podporska, T. Gumuła, Vibr. Spectrosc. 48 (2008) 263 (https://doi.org/10.1016/j.vibspec.2008.02.020).