Microstructure, roughness, and corrosion resistance of X5CrNi18-10 austenite stainless steel welded joint Extended abstract

Main Article Content

Abstract

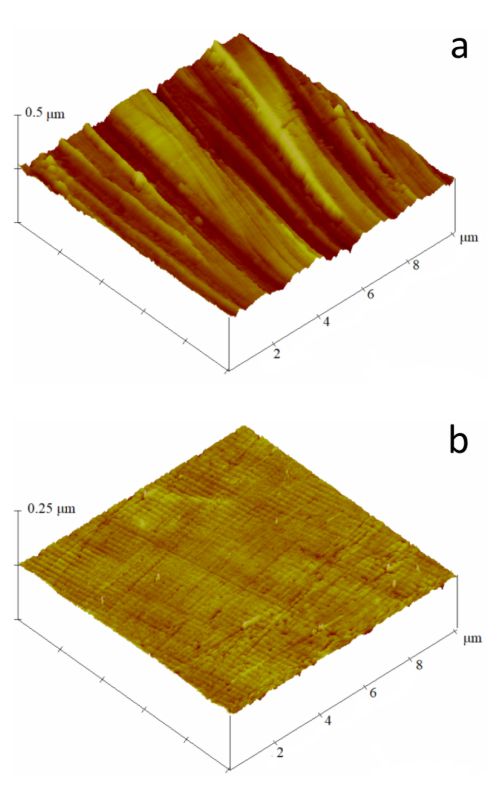

The influence of the microstructure of X5CrNi18-10 stainless steel welded joint on its resistance to general, pitting, and intergranular corrosion was analyzed. The structure of weld metal, heat affected zone (HAZ) and base metal before and after electrochemical testing was analyzed using SEM/EDS. The influence of the roughness level of the welded joint on its resistance to the mentioned types of corrosion was also examined. Although the degree of sensitization of HAZ was significantly lower than the limit value, HAZ showed a noticeably greater tendency to general and pitting corrosion than weld metal and base metal. Polishing has been shown to improve significantly the corrosion resistance of HAZ than in other parts of a welded joint.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

References

H. Bohni, Localized Corrosion of Passive Metals, in Uhlig`s Corrosion Handbook, R. W. Revie, Ed., John Wiley & Sons, Inc, Hoboken, NJ, 2011, p. 157 (https://doi.org/ 10.1002/9780470872864)

J. R. Davis, Corrosion of Weldments, ASM International, Materials Park, OH, 2006, p. 43 (https://doi.org/10.1361/corw2006p001)

A. Chiba, I. Muto, Y. Sugawara, N. Hara, J. Electrochem. Soc. 160 (2013) C511 (https://doi.org/10.1149/2.081310jes)

N. Ida, I. Muto, Y. Sugawara, N. Hara, J. Electrochem. Soc. 164 (2017) C779 (https://doi.org/10.1149/2.1011713jes)

B. T. Lu, Z. K. Chen, J. L. Luo, B. M. Patchett, Z. H. Xu, Electrochim. Acta 50 (2005) 1391 (http://dx.doi.org/10.1016/j.electacta.2004.08.036)

B. Jegdić, B. Bobić, B. Radojković, B. Alić, Lj. Radovanović, J. Mater. Process. Technol. 266 (2019) 579 (https://doi.org/10.1016/j.jmatprotec.2018.11.029)

B. Radojković, J. Kovačina, B. Jegdić, B. Bobić, B. Alić, D. Marunkić, A. Simović, Mater. Corros. (2020) 1, accepted (https://doi.org/10.1002/maco.202012039)

H. Ezuber, A. Alshater, S. O. Nisar, A. Gonsalvez, S. Aslam, Surf. Eng. Appl. Electrochem. 54 (2018) 73 (https://doi.org/10.3103/S1068375518010039)

M. J. Seo, H.-S. Shim, K. M. Kim, S.-I. Hong, D. H. Hur, Nucl. Eng. Des. 280 (2014) 62 (http://dx.doi.org/10.1016/j.nucengdes.2014.08.023)

S. Reinemann, P. Rosemann, M. Babutzka, J. Lehmann, A. Burkert, Mater. Corros. 70 (2019) 1776 (https://doi.org/10.1002/maco.201910874).