Investigation of corrosion causes and failures in the interior metal components of an automobile Scientific paper

Main Article Content

Abstract

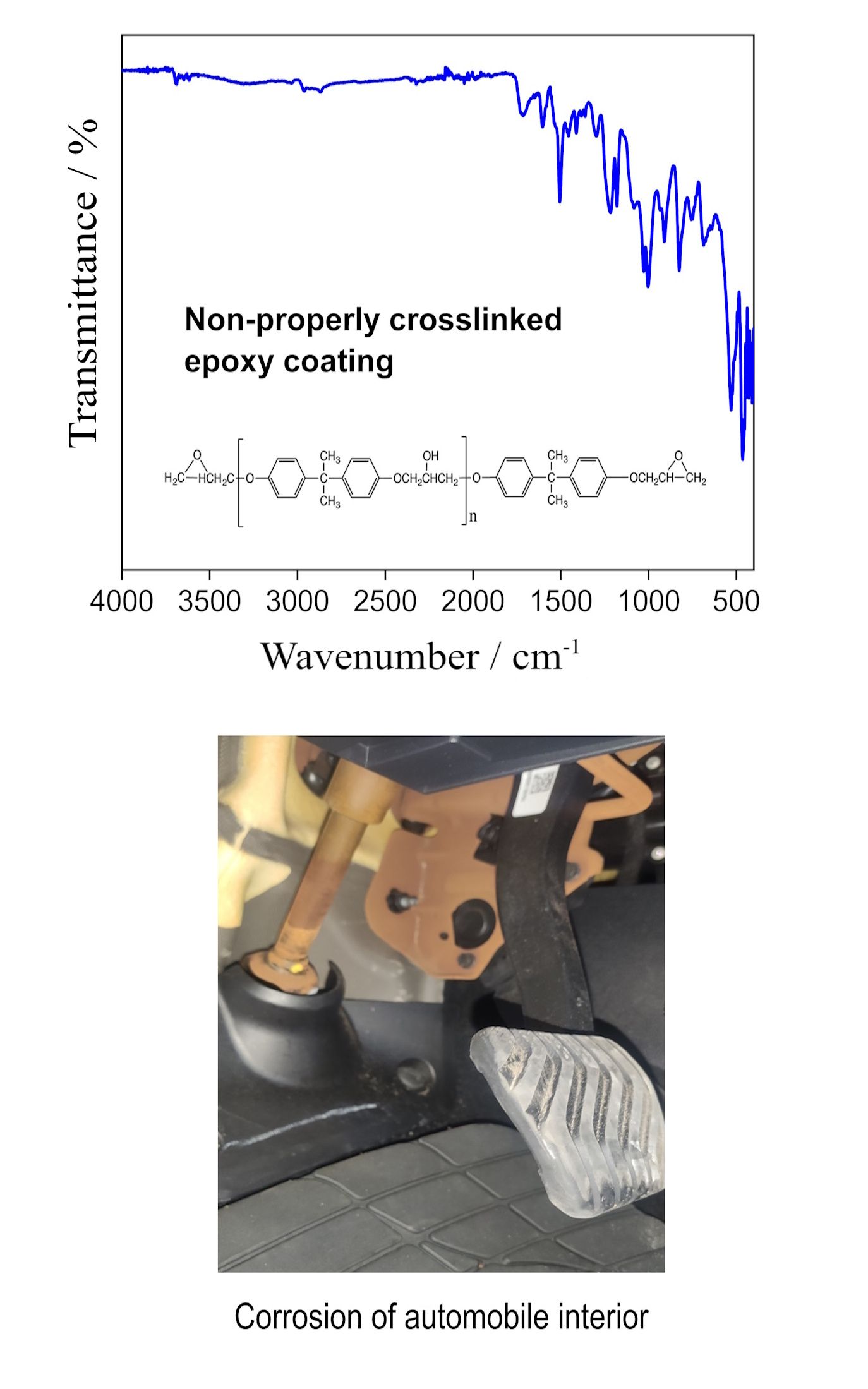

The extent of corrosion and the underlying causes of damage to the interior metal components of a one-year-old automobile from a known brand, owned by a rental car company in Serbia, were investigated. The vehicle’s interior, including upholstery and carpeting, showed no chemical spills or other damage. The solution obtained after rinsing a carpet sample from the car floor exhibited neutral pH. The corrosion behavior of the analyzed samples was determined using electrochemical impedance spectroscopy (EIS), linear polarization resistance (LPR) and linear sweep voltammetry (LSV, Tafel method). X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FTIR) analyses showed that corrosion products taken from corroded steel parts contain akaganeite β-FeO(OH) and iron (II) chloride. FTIR analysis of the organic coating revealed that the applied epoxy layer was insufficiently crosslinked, making it permeable to moisture and chloride ions. Electrochemical corrosion measurements on steel with a similar chemical composition demonstrated an increased corrosion rate in a solution containing dissolved corrosion products compared to a reference solution. This accelerated corrosion was attributed to the acidity of akaganeite and iron (II) chloride, formed due to the vehicle’s exposure to a humid and chloride-rich environment.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-136/2025-03/200026;451-03-136/2025-03/200175;451-03-136/2025-03/ 200135

References

L. J. Korb, D. L. Olson, in ASM Handbook, Volume 13: Corrosion, ASM International, Materials Park, OH, 1987

A. Kumar, J. Singh, Proc. Eng. Sci. 4 (2022) 13 (https://doi.org/10.24874/PES04.01.003)

D. Mizuno, S. Suzuki, S. Fujita, N. Hara, Corros. Sci. 83 (2014) 217 (http://dx.doi.org/10.1016/j.corsci.2014.02.020)

K. Dhonde, M. Mirhassani, E. Tam, S.Sawyer-Beaulieu, Materials 15 (2022) 3211 (https://doi.org/10.3390/ma15093211)

S. Sawyer-Beaulieu, E. Tam, A. Hussein, Materials 15 (2022) 3053 (https://doi.org/10.3390/ma15093053)

E. Díaza, L. Soria, J. M. Gallardo, Eng. Fail. Anal. 105 (2019) 828 (https://doi.org/10.1016/j.engfailanal.2019.07.022)

F. Bergh, G.C. Silva, C. Silva, P. Paiva, Eng. Fail. Anal. 129 (2021) 105679 (https://doi.org/10.1016/j.engfailanal.2021.105679)

J. Gweon, J. Park, W.K. Lee, D.Y. Kim, H. Jang, Eng. Fail. Anal. 128 (2021) 105583 (https://doi.org/10.1016/j.engfailanal.2021.105583)

C. Langer, W. Wendland, K. Honold, L. Schmidt, J.S. Gutmann, M. Dornbusch, Eng. Fail. Anal. 91 (2018) 255 (https://doi.org/10.1016/j.engfailanal.2018.04.031)

D. H. Sohn, Y. Lee, H. J. Jang, S. Y. Cho, Corros. Sci. Technol. 21 (2022) 1 (https://doi.org/10.14773/cst.2022.21.1.1)

L. Kosec, A. Nagode, G. Kosec, D. Kovacevic, B. Karpe, B. Zorc, B. Kosec, Case Stud. Eng. Fail. Anal. 4 (2015) 100 (http://dx.doi.org/10.1016/j.csefa.2013.12.004)

N. Solomon, I. Solomon, Eng. Fail. Anal. 92 (2018) 44 (https://doi.org/10.1016/j.engfailanal.2018.04.049)

M. Torkar, M. Godec, Eng. Fail. Anal. 10 (2003) 325 (https://doi.org/10.1016/S1350-6307(02)00069-9)

M. Godec, Dj. Mandrino, M. Jenko, Eng. Fail. Anal. 16 (2009) 1252 (https://doi.org/10.1016/j.engfailanal.2008.08.022)

M. I. Khana, M. A. Khan, A. Shakoor, Eng. Fail. Anal. 85 (2018) 77 (https://doi.org/10.1016/j.engfailanal.2017.12.001)

E. Arslan, K. Genel, Eng. Fail. Anal. 153 (2023) 107569 (https://doi.org/10.1016/j.engfailanal.2023.107569)

R. W. Revie, H. H. Uhlig, Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering, John Wiley and Sons, Hoboken, NJ, 2008 (https://doi.org/10.1002/9780470277270)

J. Labbe, J. Ledion, F. Hui, Corros. Sci. 50 (2008) 1228 (https://doi.org/10.1016/j.corsci.2007.08.023)

T. Misawa, T. Kyuno, W. Suetaka, S. Shimodaira, Corros. Sci. 11 (1971) 35 (https://doi.org/10.1016/S0010-938X(71)80072-0)

T. Misawa, T. Kyuno, W. Suetaka, S. Shimodaira, Corros. Sci. 14 (1974) 279 (https://doi.org/10.1016/S0010-938X(74)80037-5)

S. Reguer, F. Mirambet, E. Dooryhee, J. Hodeau, P. Dillmann, P. Lagarde, Corros. Sci. 51 (2009) 2795 (https://doi.org/10.1016/j.corsci.2009.07.012)

K. Stahl, K. Nielsen, J. Jiang, B. Lebech, J. Hanson, P. Norby, J. Lanschot, Corros. Sci. 45 (2003) 2563 (https://doi.org/10.1016/S0010-938X(03)00078-7)

M. Gilberg, N. Seeley, Stud. Conserv. 26 (1981) 50 (https://doi.org/10.1179/sic.1981.26.2.50)

ASTM A29: Standard Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought, ASTM International, West Conshohocken, PA, 2023

ASTM-G59: Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements, ASTM International, West Conshohocken, PA, 2023

S. Papavinasamt, in Techniques for corrosion monitoring, L. Yang, Ed., Woodhead Pub-lishing, Cambridge, 2008, p. 49 (https://doi.org/10.1016/B978-0-08-103003-5.00003-5)

ASTM G1: Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, ASTM International, West Conshohocken, PA, 2023

ASTM G102: Calculation of Corrosion Rates and Related Information from Electrochemical Measurements, ASTM International, West Conshohocken, PA, 2023

G. Nauer, P. Strecha, N. Brinda-Konopik, G. Liptay, J. Therm. Anal. 30 (1985) 813 (https://doi.org/10.1007/bf01913309)

S. Bashir, R. W. McCabe, C. Boxall, M. S. Leaver, D. Mobbs, J. Nanopart. Res. 11 (2008) 701 (https://doi.org/10.1007/s11051-008-9467-z)

L. Mei, L. Liao, Z. Wang, C. Xu, Adv. Mater. Sci. Eng. 2015 (2015) 250836 (https://doi.org/10.1155/2015/250836)

M. Amini, Y. Mousazade, Z. Zand, M. Bagherzadeh, M. M. Najafpour, Sci. Rep. 11 (2021) 6642 (https://doi.org/10.1038/s41598-021-85672-x)

J. B. Lambert, H. F. Shurvell, R. G. Cooks, Introduction to Organic Spectroscopy, 1st ed., Macmillan, New York, 1987

P. Maity, S. V. Kasisomayajula, V. Parameswaran1, S. Basu, N. Gupta, IEEE T. Dielect. El. In. 15 (2008) 63 (https://doi.org/10.1109/T-DEI.2008.4446737)

S. Zlatković, G. S. Nikolić, J. V. Stamenković, Chem. Ind. 57 (2003) 563 (https://doi.org/10.2298/HEMIND0311563Z)

G. Nikolic, S. Zlatkovic, M. Cakic, S. Cakic, C. Lacnjevac, Z. Rajic, Sensors 10 (2010) 684 (https://doi.org/10.3390/s100100684)

M. G. González, J. C. Cabanelas, J. Baselga, in Infrared Spectroscopy – Materials Science, Engineering and Technology, T. Theophanides Ed., InTech, London, 2012 (https://doi.org/10.5772/36323)

L.A. Teixeira, V.D.L. Junior, S.M. da Luz, in Proceedings of 16th Brazilian Polymer Conference (16 CBPOL), Ouro Preto-MG, Brazil, October 24–28, 2021, p. 1338 (http://e-democracia.com.br/cbpol/anais/2021/pdfs/plenary/4DPJ.pdf)

D. S. Achilias, M. M. Karabela, E. A. Varkopoulou, I. D. Sideridou, J. Macromol. Sci., A 49 (2012) 630 (https://doi.org/10.1080/10601325.2012.696995)

N. Rajagopalan, A. S. Khanna, J. Coat. 2014 (2014) 515470 (https://doi.org/10.1155/2014/515470)

C. Rémazeilles, Ph. Refait, Corros. Sci. 49 (2007) 844 (https://doi.org/10.1016/j.corsci.2006.06.003)

L. S. Selwyn, in ASM Handbook, Volume 13C: Corrosion: Environments and Industries, S. D. Cramer, B. S. Covino, Jr., Eds., ASM International, Materials Park, OH, 2006, p. 306 (ISBN: 978-0-87170-709-3)

A. Askey, S. B. Lyon, G. E. Thompson, J. B. Johnson, G. C. Wood, M. Cooke, P. Sage, Corros. Sci. 34 (1993) 233 (https://doi.org/10.1016/0010-938X(93)90004-Z)

B. Hirschorn, M. E. Orazem, B. Tribollet, V. Vivier, I. Frateur, M. Musiani, J. Electrochem. Soc. 157 (2010) C458 (https://doi.org/10.1149/1.3499565)

L. G. Ecco, S. Rossi, F. Deflorian, M. Fedel, J. Electrochem. Soc. 165 (2018) C933 (https://doi.org/10.1149/2.0371814jes).