Application aspects of joint anaphoresis/substrate anodization in production of biocompatible ceramic coatings Survey

Main Article Content

Abstract

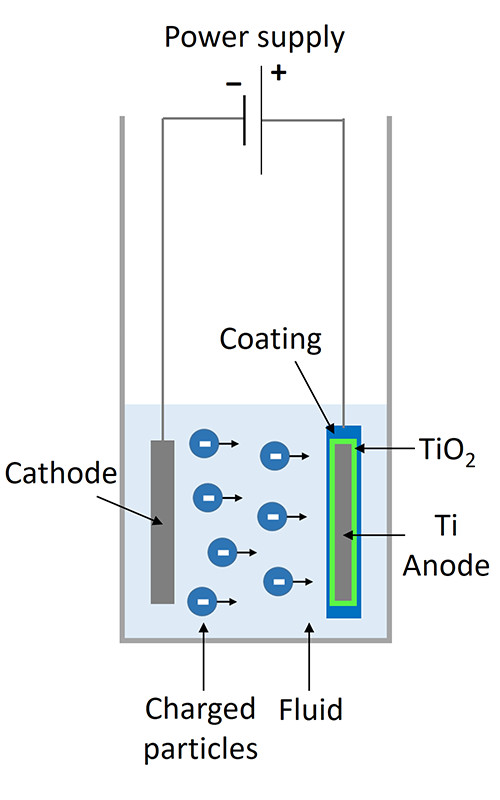

Electrophoretic deposition (EPD) can occur as a cataphoretic deposition – the coating is deposited on the cathode, and anaphoretic deposition – the coating is deposited on the anode. The primary purpose of EPD is to obtain compact and uniform organic/inorganic coatings of the desired thickness and adhesion on metal surfaces by applying an electric field to the particles of coating precursor. EPD basic principles for coatings deposition concerning fundamental explanations and considerations of practical parameters of the process are presented. Cataphoretic deposition has become popular because it can apply organic coatings to complex structures that are otherwise very difficult to coat. These coatings were found to improve the characteristics of the substrate, such as biocompatibility, appearance and resistance to the corrosion processes. The key EPD parameters are composition, pH value and viscosity of deposition medium, as well as zeta potential of the particles, electric field strength, etc. A special survey is given to the process of anaphoretic deposition, which is relatively new, and its advantages over cataphoretic deposition are discussed. Through the process of joint anaphoresis/substrate anodization process, the surface of the substrate is simultaneously anodized and modified by incorporation of the foreign particles into the anodic layer. The coatings of mixed composition of better adhesion and corrosion resistance with respect to cataphoretically-deposited coatings are obtained as result.

Downloads

Metrics

Article Details

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution license 4.0 that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

Funding data

-

Ministarstvo Prosvete, Nauke i Tehnološkog Razvoja

Grant numbers 451-03-68/2022-14/200026

References

G. Choi, A. H. Choi, L. A. Evans, S. Akyol, B. Ben-Nissan, J. Am. Ceram. Soc. 103 (2020) 5442 (https://doi.org/10.1111/jace.17118)

J. Peña, I. Izquierdo-Barba, M. A. García, M. Vallet-Regí, J. Eur. Ceram. Soc. 26 (2006) 3631 (https://doi.org/10.1016/j.jeurceramsoc.2005.12.028)

B. D. Hahn, D. S. Park, J. J. Choi, J. Ryu, W. H. Yoon, J. H. Choi, H. E. Kim, S. G. Kim, Surf. Coatings Technol. 205 (2011) 3112 (https://doi.org/10.1016/j.surfcoat.2010.11.029)

I. Ullah, M. A. Siddiqui, H. Liu, S. K. Kolawole, J. Zhang, S. Zhang, L. Ren, K. Yang, ACS Biomater. Sci. Eng. 6 (2020) 1355 (https://doi.org/10.1021/acsbiomaterials.9b01396)

W. Yuan, J. Ji, J. Fu, J. Shen, J. Biomed. Mater. Res., B 85 (2008) 556 (https://doi.org/10.1002/jbm.b.30979)

N. Meyer, L. R. Rivera, T. Ellis, J. Qi, M. P. Ryan, A. R. Boccaccini, Coatings 8 (2018) 27 (https://doi.org/10.3390/coatings8010027)

L. Besra, M. Liu, Prog. Mater. Sci. 52 (2007) 1 (https://doi.org/10.1016/j.pmatsci.2006.07.001)

S. A. Batool, A. Wadood, S. W. Hussain, M. Yasir, M. A. Ur Rehman, Surfaces 4 (2021) 205 (https://doi.org/10.3390/surfaces4030018)

S. H. Lee, S. P. Woo, N. Kakati, D. J. Kim, Y. S. Yoon, Energies 11 (2018) 3122 (https://doi.org/10.3390/en11113122)

L. Kremser, D. Blaas, E. Kenndler, Electrophoresis 25 (2004) 2282 (https://doi.org/10.1002/elps.200305868)

A. Laska, M. Bartmański, Inżynieria Mater. 1 (2020) 20 (https://doi.org/10.15199/28.2020.1.3)

N. Sato, M. Kawachi, K. Noto, N. Yoshimoto, M. Yoshizawa, Phys., C 357–360 (2001) 1019 (https://doi.org/10.1016/S0921-4534(01)00510-X)

S. Cabanas-Polo, A. R. Boccaccini, J. Eur. Ceram. Soc. 36 (2016) 265 (https://doi.org/10.1016/j.jeurceramsoc.2015.05.030)

A. A. Sadeghi, T. Ebadzadeh, B. Raissi, S. Ghashghaie, Ceram. Int. 39 (2013) 7433 (https://doi.org/10.1016/j.ceramint.2013.02.087)

B. Ouedraogo, J. Sci. Res. Reports 2 (2013) 190 (https://doi.org/10.9734/jsrr/2013/2559)

B. Ferrari, R. Moreno, Mater. Lett. 28 (1996) 353 (https://doi.org/10.1016/0167-577X(96)00075-4)

B. Ferrari, R. Moreno, J. Eur. Ceram. Soc. 30 (2010) 1069 (https://doi.org/10.1016/j.jeurceramsoc.2009.08.022)

I. Aznam, J. C. W. Mah, A. Muchtar, M. R. Somalu, M. J. Ghazali, J. Zhejiang Univ. Sci. A 19 (2018) 811 (https://doi.org/10.1631/jzus.A1700604)

M. Předota, M. L. Machesky, D. J. Wesolowski, Langmuir 32 (2016) 10189 (https://doi.org/10.1021/acs.langmuir.6b02493)

S. Kamble, S. Agrawal, S. Cherumukkil, V. Sharma, R. V. Jasra, P. Munshi, ChemistrySelect 7 (2022) e202103084 (https://doi.org/10.1002/slct.202103084)

A. A. Abdeltawab, M. A. Shoeib, S. G. Mohamed, Surf. Coatings Technol. 206 (2011) 43 (https://doi.org/10.1016/j.surfcoat.2011.06.034)

I. Zhitomirsky, J. Eur. Ceram. Soc. 18 (1998) 849 (https://doi.org/10.1016/S0955-2219(97)00213-6)

R. N. Basu, C. A. Randall, M. J. Mayo, J. Am. Ceram. Soc. 84 (2001) 33 (https://doi.org/10.1111/j.1151-2916.2001.tb00604.x)

A. Rousta, D. Dorranian, Trans. Inst. Met. Finish. 99 (2021) 172 (https://doi.org/10.1080/00202967.2021.1914382)

P. Zhao, L. J. LeSergent, J. Farnese, J. Z. Wen, C. L. Ren, Electrochem. Commun. 108 (2019) 106558 (https://doi.org/10.1016/j.elecom.2019.106558)

A. M. A. Abudalazez, S. R. Kasim, A. B. Ariffin, Z. A. Ahmad, Int. J. Eng. Res. Africa 8 (2012) 47 (https://doi.org/10.4028/www.scientific.net/JERA.8.47)

H. C. Hamaker, Trans. Faraday Soc. 35 (1940) 279 (https://doi.org/10.1039/TF9403500279)

R. Moreno, B. Ferrari, in: Electrophor. Depos. Nanomater., J.H. Dickerson, A.R. Boccaccini, Eds., Springer. New York, 2012, p. 73 (https://doi.org/10.1007/978-1-4419-9730-2_2)

A. I. Avgustinik, V. S. Vigdergauz, G. I. Zhuravlev, J. Appl. Chem. USSR (Engl. Transl.) 35 (1962) 2090 (https://jglobal.jst.go.jp/en/detail?JGLOBAL_ID=201602000824298251)

P. M. Biesheuvel, H. Verweij, J. Am. Ceram. Soc. 82 (1999) 1451 (https://doi.org/10.1111/j.1151-2916.1999.tb01939.x)

P. Sarkar, P. S. Nicholson, J. Am. Ceram. Soc. 79 (1996) 1987 (https://doi.org/10.1111/j.1151-2916.1996.tb08929.x)

G. J. Kynch, Trans. Faraday Soc. 48 (1952) 166 (https://doi.org/10.1039/tf9524800166)

G. Anné, K. Vanmeensel, J. Vleugels, O. Van Der Biest, J. Am. Ceram. Soc. 88 (2005) 2036 (https://doi.org/10.1111/j.1551-2916.2005.00387.x)

V. Ozhukil Kollath, Q. Chen, R. Closset, J. Luyten, K. Traina, S. Mullens, A. R. Boccaccini, R. Cloots, J. Eur. Ceram. Soc. 33 (2013) 2715 (https://doi.org/10.1016/j.jeurceramsoc.2013.04.030)

A. Braem, K. De Brucker, N. Delattin, M. S. Killian, M. B. J. Roeffaers, T. Yoshioka, S. Hayakawa, P. Schmuki, B. P. A. Cammue, S. Virtanen, K. Thevissen, B. Neirinck, ACS Appl. Mater. Interfaces 9 (2017) 8533 (https://doi.org/10.1021/acsami.6b16433)

E. J. W. Verwey, J. T. G. Overbeek, Theory of the Stability of Lyophobic Colloids: The Interaction of Sol Particles Having an Electric Double Layer, Elsevier, New York, 1948 (http://www.damtp.cam.ac.uk/user/gold/pdfs/teaching/BPFD/Chap2_10_VerweyOverbeek.pdf)

B. Derjaguin, L. Landau, Prog. Surf. Sci. 43 (1993) 30 (https://doi.org/10.1016/0079-6816(93)90013-L)

J. H. Adair, E. Suvaci, J. Sindel, in: Encycl. Mater. Sci. Technol., K.H. Jürgen Buschow, R.W. Cahn, M.C. Flemings, B. Ilschner, E.J. Kramer, S. Mahajan, P. Veyssière, Eds., Elsevier, Amsterdam, 2001, p. 8996 (https://doi.org/10.1111/j.2042-7158.1951.tb13130.x)

S. Eraković, A. Janković, D. Veljović, E. Palcevskis, M. Mitrić, T. Stevanović, D. Janaćković, V. Miskovic-Stankovic, J. Phys. Chem., B 117 (2013) 1633 (https://doi.org/10.1021/jp305252a)

S. Erakovic, A. Jankovic, G. C. P. Tsui, C. Y. Tang, V. Miskovic-Stankovic, T. Stevanovic, Int. J. Mol. Sci. 15 (2014) 12294 (https://doi.org/10.3390/ijms150712294)

J. Li, P. Zhou, S. Attarilar, H. Shi, Coatings 11 (2021) 647 (https://doi.org/10.3390/coatings11060647)

C. Yao, T. J. Webster, J. Nanosci. Nanotechnol. 6 (2006) 2682 (https://doi.org/10.1166/jnn.2006.447)

Y. Parcharoen, P. Termsuksawad, S. Sirivisoot, J. Nanomater. 2016 (2016) 9143969 (https://doi.org/10.1155/2016/9143969)

M. R. Pantović Pavlović, M. M. Pavlović, S. Eraković, T. Barudžija, J. S. Stevanović, N. Ignjatović, V. V. Panić, J. Serb. Chem. Soc. 84 (2019) 1305 (https://doi.org/10.2298/JSC190730105P)

M. R. Pantović Pavlović, S. G. Eraković, M. M. Pavlović, J. S. Stevanović, V. V Panić, N. L. Ignjatović, Surf. Coatings Technol. 358 (2019) 688 (https://doi.org/10.1016/j.surfcoat.2018.12.003)

M. R. Pantović Pavlović, M. M. Pavlović, S. Eraković, J. S. Stevanović, V. V. Panić, N. Ignjatović, Mater. Lett. 261 (2020) 127121 (https://doi.org/10.1016/j.matlet.2019.127121)

M. R. Pantović Pavlović, B. P. Stanojević, M. M. Pavlović, M. D. Mihailović, J. S. Stevanović, V. V. Panić, N. L. Ignjatović, ACS Biomater. Sci. Eng. 7 (2021) 3088 (https://doi.org/10.1021/acsbiomaterials.1c00035)

M. R. Pantović Pavlović, M. M. Pavlović, J. N. Kovačina, B. P. Stanojević, J. S. Stevanović, V. V. Panić, N. L. Ignjatović, J. Ser. Chem. Soc. 86 (2021) 555 (https://doi.org/10.2298/JSC210211024P)

M. R. Pantović Pavlović, PhD Thesis, University of Belgrade, 2021 in Serbian (https://147.91.1.130/handle/123456789/4424)

M. R. Pantović Pavlović, N. L. Ignjatović, V. V Panić, I. I. Mirkov, J. B. Kulaš, A. L. Malešević, M. M. Pavlović, J. Funct. Biomater. 14 (2023) 227 (https://doi.org/10.3390/jfb14040227).